NEXT-GENERATION ECO-FRIENDLY DESIGNER WITH A FOCUS ON SUSTAINABILITY AND ETHICAL FASHION

When innovative thinking collides with an eco-conscious mindset, great ideas are born out of brilliant and creative minds, and Damir Lihanov happens to be one. A true representation of what the world needs to create beauty and simultaneously preserve the environment. No need for more words to describe the talent while we can showcase the creation.

A Russian fashion designer of Kazakh origins, Damir was born in Siberia, lived and worked in Hong Kong, and studied fashion in Italy, where he’s been living and working for the last 14 years. The rising star in fashion design is the founder and creative director at Constructor Studio, with headquarters in Florence, Italy. He has successfully combined his decade of expertise in accessories design and his passion for eco-friendly, sustainable, and ethical fashion to create his masterstroke: The ITEMONE modular bag.

“What you do counts; the universe responds to your actions,” said Theresa Cheung in her book, 21 Rituals to Ignite Your Intuition. Something that Damir picked up and followed in his career.

“It is what you do that counts; the universe responds to your actions,”

–Theresa Cheung

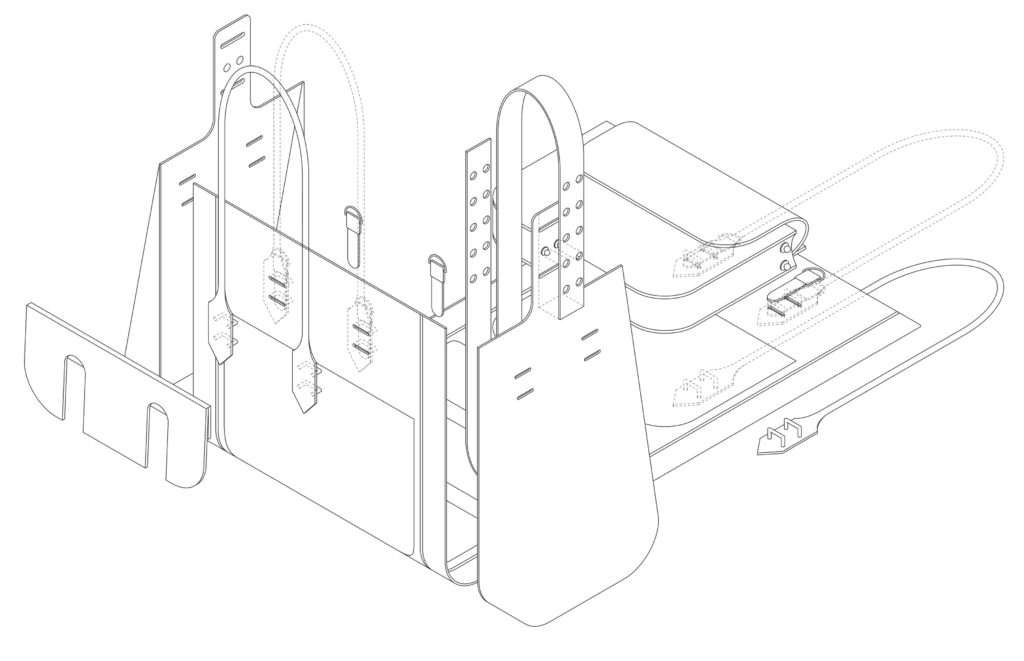

A fast-changing bag for a fast-changing world, the ITEMONE

The Transformer-like hand accessory consists of seven detachable, replaceable, and adjustable modular units. With its 7 in 1 utility, the ITEMONE bag challenges the fast fashion industry, which strives on the notion that repeating outfits is a major faux pas, leading to an overproduction of what will eventually become stocked items and a higher carbon footprint that is slowly but surely destroying the environment.

For travelers, it can be transformed into a travel bag. For businessmen and businesswomen alike, thanks to its classical and gender-neutral style, it can become a briefcase. It can be held as a shoulder bag or a clutch for a lunch date with friends or a night out. Eventually, it can be a bucket bag for those who love to shop.

How to produce fashion out of pineapple leaves?

Another important box on the sustainable and ethical fashion list proudly checked by the ITEMONE bag is the use of biodegradable, cruelty-free, and vegan textiles. For his design, Damir Lihanov uses Piñatex, a sustainable non-woven leather alternative made from the wastage of pineapples’ leaves.

This innovative alternative is credited to Dr. Carmen Hijosa, who discovered it during a visit to the Philippines. Over there, locals use natural fiber to make traditional garments known as The Barong Tagalog.

With flat parts for the customers to assemble by themselves to their liking, the ITEMONE production model discards the traditional ways of designing a leather handbag, makes the accessory a lot easier to produce, and reduces the chances of having a damaged item upon delivery.

Sustainable fashion leads to sustainable production

Digital manufacturing is perhaps the primary aspect that makes the ITEMONE bag a revolutionary and unique design. Technology has fast become imperative to propelling the environmentally-conscious wheel forward and making fashion more sustainable in recent years.

With 3D printing and AI-assisted design, technology has helped find a concrete solution to the problem of overproduction and overstocking by creating a virtual sample that can then be made according to the customers’ demand. Hence, allowing a lower rate of carbon footprint and substantially reducing waste.

The no physical production or travel aspect of digitized manufacturing responds to the ethical side of sustainable fashion. When there are no workers to build the item, there are no violations of labor laws, low living wages, and working conditions to worry about.

Such means of manufacturing owe their existence to what has become a phenomenon in the world of innovation and technology, The Fab Labs.

Compute to fabricate

MIT professor Neil Gershenfeld, the founder of digital fabrication labs and culture, defines these learning workshops and platforms as an “opportunity is to harness the inventive power of the world to locally design and produce solutions to problems as they emerge.”

They are operating as a prominent source of innovation in digitized fabrication. Fab Labs allow both the geniuses in the world and those who find themselves far less fortunate to become influential creators and key participants in the march of the 4th industrial revolution.

A network of over 2,500 labs worldwide keeps growing at an extraordinary rhythm. They can relate to agriculture in India and energy conversion in Ghana.

With their “compute to fabricate” approach to revolutionizing the industrial world. The labs focus mainly on elevating computers from their modest status as simple means to control tools and turn them into actual tools themselves. Hence, transforming the possibility of making just about anything into a reality.

As a strong sense of community flourishes inside these often small and local workshops, the consumer mindset of their contributors withers, and a much more innovative focus on making, producing, and fabricating takes over its place. Maybe that describes what happened with Damir Lihanov as he visited Fab Lab Armenia Education Foundation to carry on with his fashion line. Fab Lab and digital fabrication have enabled him to create and develop a pop-up stand/booth to showcase his constructor-bag ITEMONE in Paris, London, and Milan, together with the support of his school “Istituto Marangoni.” The “Constructor Booth” is now under development process in FabLab Armenia.

The birth of Fab Lab Armenia Education Foundation

“Fab Lab Armenia Education Foundation was born as a center and a springboard for a new generation of Armenians to foster creativity, collaboration, and entrepreneurship,” Jacqueline Karaaslanian, the interim CEO of Fab Lab Armenia Education Foundation – Dilijan, explains, empathizing the five Cs of values that run through the establishment’s digital veins: Community, Curiosity, Courage, Creativity, and Cooperation.

With a buzzing hive of educators, artists, engineers, students, and creative minds, Fab Lab Armenia Education Foundation connects local people to world-leading technologies, making the opportunity to create and innovate accessible to one and all. And with Its state-of-the-art, high-tech digital manufacturing tools such as 3D printers and laser cutters, teleportation is no longer a sci-fi myth or a superhero power that you can only read about in comics.

At Fab Lab Armenia Education Foundation, you can design and prototype any object and send it via email to another location. It will be cut, disassembled, and assembled again at its destination point. Local becomes global, and innovators and entrepreneurs alike are finally given a chance to share their creations with the world.

Aspiring to make better fashion choices and having a more eco-conscious wardrobe into a global trend, Damir Lihanov has begun his fascinating journey with his ITEMONE bag as the item currently being repackaged to reach its destined worldwide audience.

Damir Lihanov continues to push the boundaries as he researches new materials at Fab Lab Armenia Education Foundation. He explores grape leather made from grape seeds, stalks, and the fibers of the grape skin, the wine industry’s waste products. Wine leather is 100% sustainable, 100% vegan, and can be recycled. It’s said to feel smooth to the touch and is both stable and durable.

To make grape leather, extract bio-oil from the grape seeds, dry the other grape materials, and then polymerizes all the grape materials. That is then combined with natural fibers, resulting in soft, textured, plant-based leather.

“The best way of learning is to do research.”

–Joseph Zakarian

Engineer, Research–Joseph Zakarian

Engineer, Research and Development (R&D)

Fab Lab Armenia Education Foundation – Dilijan

Conclusion

With such an innovative and creative way of thinking, concern, and a desire to cause no harm to the environment, this next-generation eco-friendly Designer is focusing on sustainability and ethical fashion. Damir Lihanov will undoubtedly have a resounding success.

We can’t but wish him the best of luck in his future endeavor toward establishing a movement in the fashion industry that would impact and inspire many others worldwide.

#DamirLihanov #fablab #fablabarmenia #innovation #NeilGershenfeld #JacquelineKaraaslanian #Eco-friendly-Designer #Sustainability #EthicalFashion #ConstructorStudio #ITEMONE #DigitalManufacturing

#DigitalFabrication #SustainableFashion #SustainableFashionBrand #SustainableFashionLabel #SustainableFashionDesigner