Parametric Bodies and Modular Design in Fashion Fabrication is an innovative course exploring the future of fashion through digital tools and sustainable design. Over four hands-on sessions, participants learn to create digital mannequins, design circular modular garments, and experiment with textile, leather, and 3D printing techniques. The course emphasizes material efficiency, rapid prototyping, and creative exploration. Participants will repurpose their own materials (such as old cloth) to craft functional, sustainable designs. The program concludes with a collaborative showcase to share and inspire.

General Skills Gained:

- Digital modeling and rapid prototyping

- Sustainable fashion design with circular principles

- Using the vinyl cutter and laser cutter

- 3D printing on textiles and flexible materials

- Working with textiles, leather, and bio materials

Program Structure:

4 sessions | Saturdays

June 7–28, 2025

1:30–4:30 PM

Participants: 5

Age: 18+

Day 1 (June 7): Digital Bodies & Mannequins Creation

Goal: Understand the concept of digital bodies and learn how to create digital mannequins using MakeHuman and Slicer For Fusion.

Activity Plan:

- Intro to Digital Bodies & Mannequins Creation: Learn about digital avatars and their use in fashion and art.

- Software Introduction to CAD (Computer Aided Design) – MakeHuman – Blender – Slicer For Fusion: Basics of MakeHuman software for creating human mannequins and Blender software for customization.

- Hands-on Activity: Participants create their own 3D mannequins in MakeHuman and Slicer For Fusion. To use 2D media to create 3D shapes that are lighter and use less material. How to use 2D processes to create 3D shapes. The process allows to do rapid prototyping at a lesser cost and using less material.

- Introduction to CAM (Computer Aided Manufacturing): Preparing your digital prototype to be manufactured using a laser cutter.

Skills Gained:

- Designing and Modelling with MakeHuman, Blender, Slicer for Fusion software.

- Creating a 3D designed object and doing rapid prototyping for manufacturing.

- Going from idea to prototyping.

Day 2 (June 14): Circular Fashion & Modular Design

Goal: Learn how to design sustainable, modular fashion pieces using circular fashion principles. Experimenting with paper prototypes to test ideas.

Activity Plan:

- Intro to Circular Fashion: Understand the principles of sustainability, recycling, and modularity in fashion through a large set of concrete examples.

- Modular Design: Learn how to create shapes and patterns through the process of the many possible combinations of patterns.

- Hands-on Activity: Create paper prototypes of modular designs using scissors.

- Techniques Demo: Introduction to laser cutting for modular design.

Skills Gained:

- Master the art of using less to create more.

- Repurposing an existing material for prototyping.

- Designing from hands to using machines to ensure precision and repeatable prototypes.

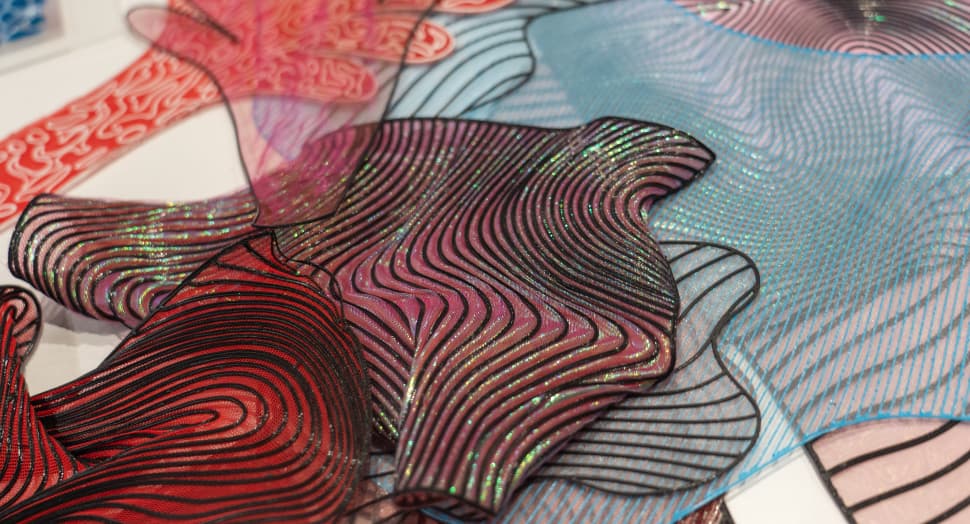

Day 3 (June 21): From Modular Design to Textile and Leather Products

Goal: Creating 2D designs, then transfer them onto fabric, and explore laser cutting and engraving techniques for textile, leather and other materials.

Activity Plan:

- 2D Design Techniques: Desirable prerequisite knowledge Inkscape, Coreldraw, Illustrator to create 2D patterns and designs for textiles and leather

- Material Exploration: Learn how to work with textiles, leather, and bio materials.

- Prototyping: Create your design, laser cut it and prepare pieces for assembly.

Skills Gained:

- Turning 2D designs into patterns for textile, leather and other materials.

- Manipulating and adjusting laser cutters for different types of material.

Used fabrics are welcome.

Day 4 (June 28): 3D Printing on Textile and Transforming the Rigid into Flexible Material

Goal: Explore 3D printing techniques for flexible design and direct printing on textile surfaces.

Activity Plan:

- Exploring flexibility in 3D design: using mesh structures, joints, and parametric modeling techniques.

- Preparing the model for printing using 3D Slicers.

- Working with 3D printers and learning the adjustment processes.

- Design or modify small pieces using Blender or a similar software, to produce wearable or decorative prototypes.

Skills Gained:

- Going from rigid to flexible materials.

- Design wearable or decorative elements using 3D modeling software.

- Processing from design to printing on fabric and flat surfaces.

Last week of August – Show & Tell for mutual inspiration.

Why register?

This workshop is your gateway into the future of fashion — where sustainability meets digital design. In just four sessions, you’ll gain hands-on experience with digital mannequins, modular garments, and advanced tools like laser cutters and 3D printers. Whether you’re a fashion enthusiast, maker, or tech explorer, this course gives you the chance to prototype your ideas, repurpose materials, and rethink how clothing is made. No prior experience needed — just curiosity and a willingness to experiment.